EGSTON Power Electronics

Power Electronics Revolution

Digital Power Twin

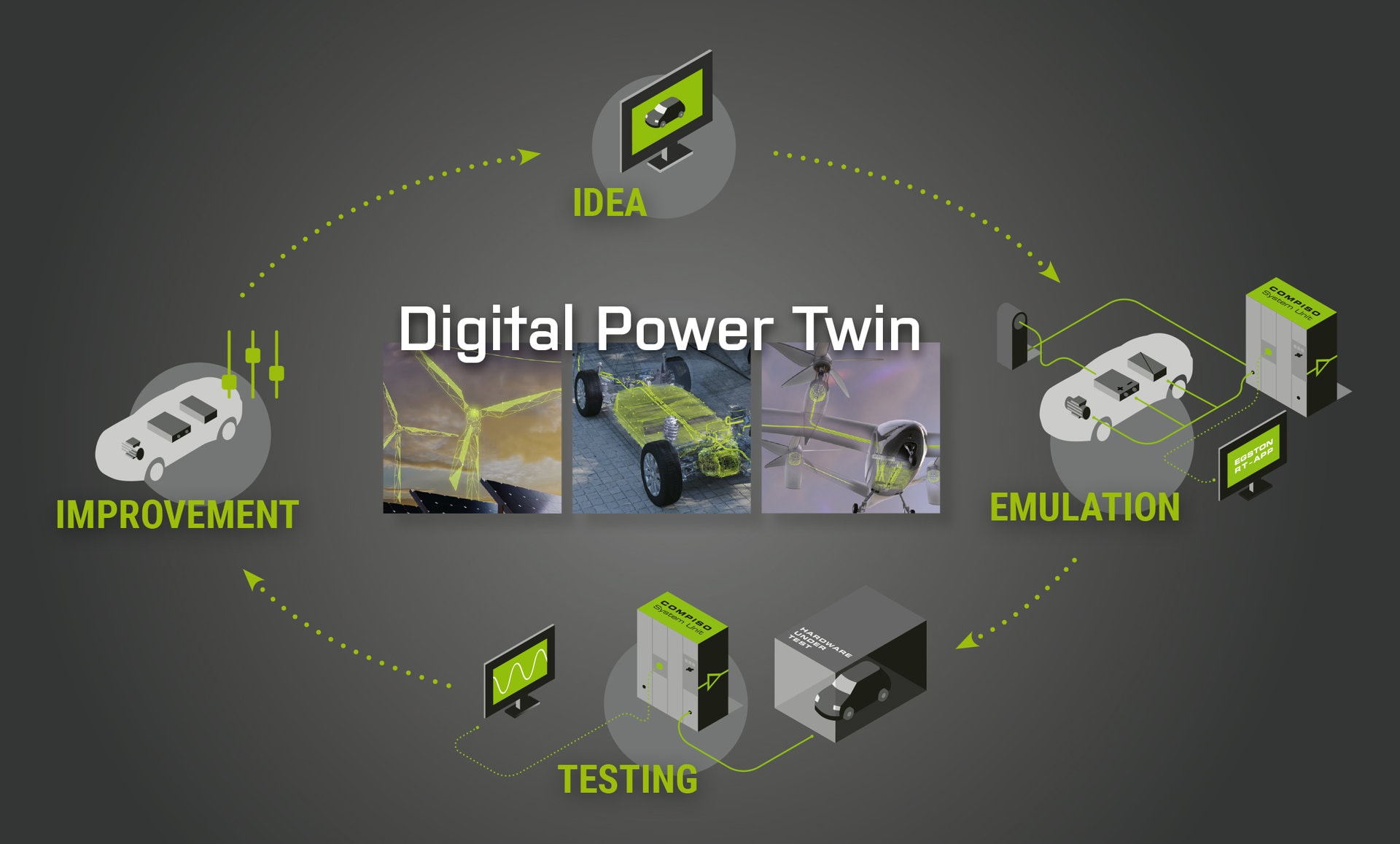

Time to market, efficient use of resources and development cost reduction are the main drivers in today’s product development lifecycles. EGSTON Power Electronics revolutionize research, product development and testing, and push even the existing tools beyond conventional limits.

Creating Digital Twins for real-time simulation purposes is a dominating trend. Now EGSTON Power Electronics take real time simulation to the next level, creating systems for emulating and testing the most powerful electrical devices before even building the first prototype. Pushing the limits what is technologically possible, we now proudly present “Digital Power Twin”, the most advanced emulation platform currently available.

The “Digital Power Twin” is a digital representation of a real electrical device, based on real-world power signals, and with real-time behavior. We use latest high-end computational resources and advanced power electronic components to create ultra-high-fidelity “Digital Power Twins” of single devices and even complete power systems. Such a “Digital Power Twins” is a combination of a virtual model and an ultra-high-fidelity power amplifier as the signal generator.

In product development processes, “Digital Power Twins” can undergo all necessary tests before the first physical prototype exists. It is noteworthy in this context that prototyping consumes a major share of the product development time and costs. Replacing physical prototypes with “Digital Power Twins” makes changing product parameters or even complete product topologies faster, easier and cheaper. Altering the digital model is a breeze, compared building another physical prototype. The “Digital Power Twin” will always behave according to the changes in the model properties, how small or big these changes are. Even testing against other components on real signal and power levels is possible, making it easy to determine whether there are critical disturbances or not.

This is a radical shortcut on the road from product idea to market: Test, alter, and retest a digitally simulated model with the help of a power amplifier on real signal and power level until the perfect solution is found. Then build the physical prototype and return to the “Digital Power Twin”: It is an extremely versatile and flexible device that you can also use so as a programmable test bench for prototypes, up to, and including certification of the final product.

Product Development Lifecycle with

Digital Power Twin

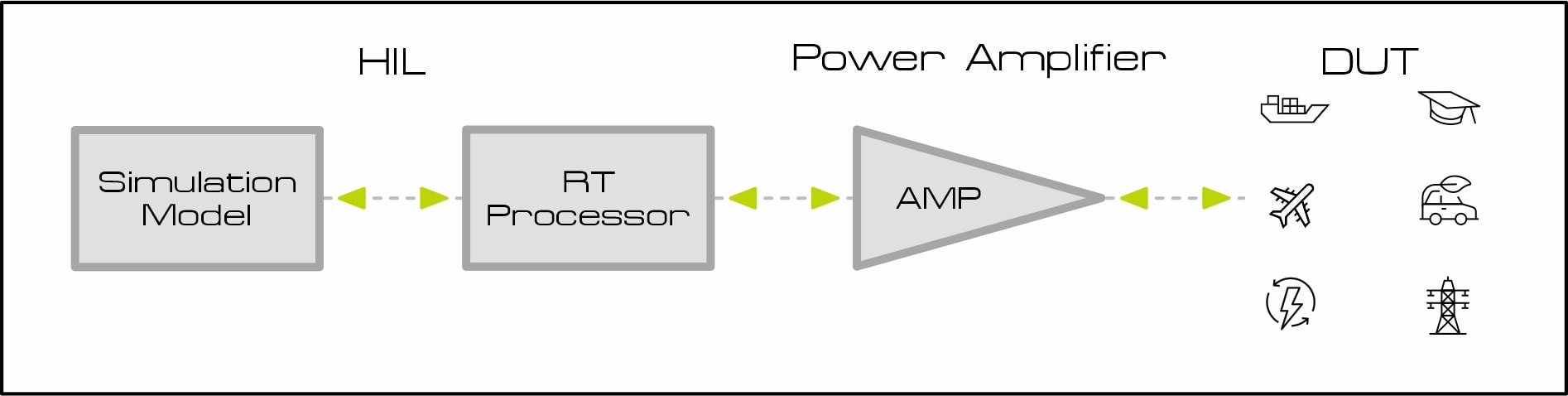

Digital Power Twin or

PHIL Setup

In the academic world, creating a replica of a real power system or device is called the “Power Hardware in the Loop”. This approach is the logical step beyond purely simulation-based “Hardware in the Loop”. The basic concept is simple: A hardware-in-the-loop real-time processor generates a digital signal which is amplified up to mega-watt level through four quadrant power amplifiers. This “Digital Power Twin” setup will perfectly emulate smart grids, generators, motors, inverters, aircraft systems, electric vehicles, batteries, solar panels, wind turbines or any other electric machine.

The process streamlining potential of “Digital Power Twins” is huge. Imagine being able to replicate a device and its system environment to predict its behavior in even the most extreme conditions without putting real hardware to risk. This revolutionary approach will benefit research laboratories, certifiers and industrial companies in many ways, reducing development time and costs while greatly increasing the overall output capacity in testing and certifying products.

Live Demo

Schedule a live demo with one of our product specialists at your convenience. We can learn about your requirements and answer your questions.